Imagine the following scenario: Your child is feeling a little under the weather and you finally make an appointment to go see your family doctor. The doctor does a cursory examination, and decides that he/she needs surgery immediately. Wouldn’t you ask for a more thorough examination? What about a CAT scan, an MRI, an EKG, or some other tests? Wouldn’t you want to see more information on what is wrong before approving the surgery? Wouldn’t you ask to see some scientific evidence that the surgery is required?

This additional testing provides evidence that allows doctors to pinpoint what is wrong and target the exact problem area. Advanced imaging techniques provide crucial information for medical professionals. Similarly, non- destructive moisture tests provide building owner’s valuable information concerning the moisture content of their building components.

Consequences of Wet Insulation

There are many reasons why it is important to identify wet insulation within a commercial roofing system. For example:

• Roof leaks can cause costly interior damage to facilities and create hazardous conditions for building occupants, such as slip hazards and/or indoor air quality concerns.

• Wet insulation becomes a conductor of energy rather than a resister, resulting in higher energy bills.

• Trapped moisture in insulation creates an environment for mold to grow and may eventually lead to indoor air quality issues.

• Wet insulation often causes roofing fasteners to corrode and reduces the uplift performance of the roof, which can lead to a roof blow off during a wind event.

• Trapped moisture can create an environment, much like steaming an envelope open, in which moisture vaporizes and releases the glue at the seams of the roofing system.

• Wet insulation will speed up the deterioration of the roofing system.

Thankfully, rather than simply doing a quick visual assessment of the roof and deciding it needs to be replaced, today’s building owners have more options. They can utilize professionals that rely on several different non-destructive moisture tests to help make reliable recommendations, based on unbiased scientific information. The decision of when to repair, restore, or replace a large commercial roof often involves a million dollar investment or more.

Thankfully, rather than simply doing a quick visual assessment of the roof and deciding it needs to be replaced, today’s building owners have more options. They can utilize professionals that rely on several different non-destructive moisture tests to help make reliable recommendations, based on unbiased scientific information. The decision of when to repair, restore, or replace a large commercial roof often involves a million dollar investment or more.

Before you make a million dollar decision, much like a medical decision, building owners should insist on more evidence to support the recommendation

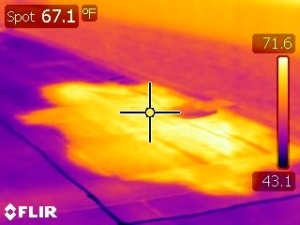

Infrared Thermography

Infrared Thermography, also known as an IR scan, is a non- destructive testing method to detect and record temperature differences across the surface of an object. IR scanning is the most common moisture detection method for identifying wet insulation on non-ballasted commercial roofing systems. During the day, wet insulation will absorb heat energy from the sun. At night, the wet, denser, insulation will retain the heat longer before releasing it into the atmosphere. Most IR scans are facilitated at night in order to capture the thermal signature anomalies located within a roofing system.

Infrared Thermography, also known as an IR scan, is a non- destructive testing method to detect and record temperature differences across the surface of an object. IR scanning is the most common moisture detection method for identifying wet insulation on non-ballasted commercial roofing systems. During the day, wet insulation will absorb heat energy from the sun. At night, the wet, denser, insulation will retain the heat longer before releasing it into the atmosphere. Most IR scans are facilitated at night in order to capture the thermal signature anomalies located within a roofing system.

It is common to outline the located thermal anomalies with spraypaint on the roof surface. This allows for the future location of the anomalies, without the use of an infrared camera. A CAD drawing is then produced which identifies the location(s) of the thermal anomalies.

IR scans work best when conditions provide a significant temperature difference between the interior and exterior of the building. Additionally, optimal conditions are at night following a sunny day and when night time temperatures cool quickly. The greater the rate of outside temperature change, the greater the difference in surface temperatures between wet and dry areas.

There are some limitations to IR scans. Ponding water or any precipitation within the last 24 hours prior to the scan may lead to inaccurate readings. IR cameras detect heat and NOT moisture. Although infrared scans can be extremely accurate, the anomalies must always be checked with a capacitance moisture meter to verify the presence of moisture.

If there are multiple roofs on the building and moisture is trapped in the lower roof, an IR scan will not detect this as an anomaly, as only the temperature of the surface roof will be detected by the camera.

It is important to remember that IR scanning works on the principle of solar gain and temperature difference. Wind can produce a false anomaly on roofing systems, as friction is created which heats up the roof membranes. Additionally, some roof constructions can produce false readings with IR scans such as ballasted systems, lightweight concrete decks, and roofs with highly reflective roof surfaces. Most IR scans are done in the summer when the solar gain is greatest. As cooler temperatures arrive in the fall/winter, it is very difficult to get accurate results because the solar temperature gain is limited.

Nuclear Scans

Nuclear scans use a gauge to detect various levels of hydrogen ions trapped within roof systems. The readings displayed by the gauge are a measurement of the quantity of hydrogen ions that are present within a detectable area beneath the gauge. Since hydrogen ions are present in water, these readings can be correlated to moisture content, once a baseline reading for a dry area has been established.

The readings are used to create a map of the wet areas on the roof plan, which again show the location and outline of the suspected wet areas. Areas with wet insulation will have greater concentrations of hydrogen than those with dry insulation. This method of data collection shows where the moisture levels are highest, allowing the source of the leak to be more easily determined.

With nuclear roof scans, the entire roof is typically marked in a 5’ x 5’ or 10’ x 10’ grid pattern. Within each grid point, a reading is taken and recorded on a roof plan. The smaller the grid pattern, the more data points are collected. For example, a 10,000 square foot roof with a 10’ x 10’ grid would require 100 data points. If the grid were 5’ x 5’, there would be 400 data points.

Obviously, more data points will provide more accurate information, but will also take longer and therefore be more costly. An experienced technician often narrows the grid pattern in areas with wet insulation to better pinpoint problem areas. A core cut is taken in areas with the highest readout to verify moisture is in the insulation components.

The nuclear scan readings can miss small areas of wet insulation, because the actual readings are taken on a very small proportion of the total roof. Taking nuclear scans on larger roofs will take significantly more time than taking infrared scans. However, nuclear roof moisture scans are performed during the day and are not affected by debris on the roof, winds, or reflective roof coatings.

Electronic Field Vector Mapping (EFVM)

Electronic Field Vector Mapping (EFVM) takes a different approach when it comes to nondestructive moisture tests. Whereas the goal of infrared and nuclear scans is to locate wet insulation, the goal of EFVM is to locate the point where moisture can enter a roof system. EFVM begins with a grounded wire loop around a given roof section – typically 5,000 to 20,000 square feet. A technician then applies water over the surface of the test

area, using the water as a conductive medium. A low-voltage, pulsating electric charge is created between the non-conductive roof system and the conductive structural deck.

Watertight roofs will isolate the difference whereas a puncture or point of entry will cause an electrical connection to occur. Trained technicians read the directional flow of the current and pinpoint the exact point of moisture entry into the roof system.

One advantage of EFVM is that once the point entry is detected, it can be repaired and then re-checked that it has been repaired accurately. Although EFVM can be used on a variety of low slope roof systems, it is most often used on roofs where finding a leak poses difficulties, such as vegetated roof systems, ballasted single plies, and inverted roof membrane assemblies.

Capacitance Moisture Meters

Capacitance Moisture Meters scans are the only method that actually detects moisture. The other methods all have to be verified with a moisture meter to verify that he located anomalies are actually wet. The capacitance meter works by transmitting a signal between two electrodes in the meter. The speed that the signal is transmitted is calculated and formulated into a moisture reading. This occurs because the signal is calibrated at a certain speed; the presence of moisture will speed up the signal, resulting in a “wet” reading on the meter.

Capacitance Moisture Meters scans are the only method that actually detects moisture. The other methods all have to be verified with a moisture meter to verify that he located anomalies are actually wet. The capacitance meter works by transmitting a signal between two electrodes in the meter. The speed that the signal is transmitted is calculated and formulated into a moisture reading. This occurs because the signal is calibrated at a certain speed; the presence of moisture will speed up the signal, resulting in a “wet” reading on the meter.

Due to the fact that the meter must contact the entire surface of the roofing system, the process can be time consuming and therefore more expensive than other methods. Therefore, it is most often used on roofs where finding a leak poses difficulties, such as vegetated roof systems, ballasted single plies, and inverted roof membrane assemblies.

Non-Destructive Moisture Tests Save Owners Money

Non-destructive testing provides roofing professionals and building owners with valuable information to make sound business decisions about their roofing assets. Valuable information gathered from nondestructive moisture scans can help building owners and facility managers extend the life of their roofing assets. Prematurely replacing a roof that can be repaired or restored costs building owners millions of dollars annually. By using nondestructive moisture tests, the question of “repair vs. replace” is answered with hard data.

Although most nondestructive tests are commonly performed on agingroof systems, many design and roofing professionals are now requiring nondestructive tests on newly installed roofs as a measure of quality assurance. In fact, some manufacturers require them as a condition of the warranty. This requirement is written directly into the specification and virtually guarantees that the new roof is sound, watertight, and contains no trapped moisture.

Conclusion

As with many advanced technologies, trained and skilled people are just as important as great technology. Qualified professionals are needed to perform these tests and interpret the results. Similarly, a design professional or trained roofing expert must then use this valuable information:

• in combination with core cuts and visual inspections

• to create a game plan that maximizes the building owners’ roofing investment

The medical profession has used advanced imaging techniques for decades to pinpoint problems and keep us healthy. Similar technology is now available for building owners and facility managers to help extend the life of their roofing assets. Require a nondestructive scan before you replace your next roof and you will likely save thousands of dollars!